This device is designed for the speedy and hygienic production of chips made from beverage cans, glass and plastic bottles, and other plastic products containing expired substances. Reduce personnel costs, increase throughput, and improve sales value with the chips produced, all while contributing greatly to the recycling and reuse of resources.

(1) Simply insert the containers, and this fully-automated machine will take care of the crushing, cleaning and drying.

(2) Management and transport is made simple by packing chips in flexible container bags.

(3) Washing prevents the occurrence of insects and offensive odors.

(4) Only half the personnel necessary for press machining is required.

(5) Processing capacity is three times that of press machines.

(6) Ability to process 400 cases per hour.

*These features may vary according to container shape, mass, etc.

The above strengths are highly regarded by major beverage manufacturers who have introduced multiple Hamada recycling systems into their factories.

[Crushing, cleaning, and drying machine for unopened containers]

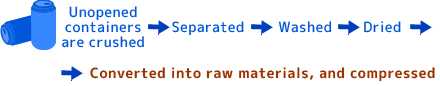

Unopened containers are crushed→separated→washed→dried→converted into raw materials, and compressed. After being placed on the conveyor, unopened beverage containers are crushed into pieces and their content removed. The small pieces are then washed and dried before being packed in flexible containers for easy storage and transportation.

Feel free to contact us or request materials